Inventory AI | Replenishment

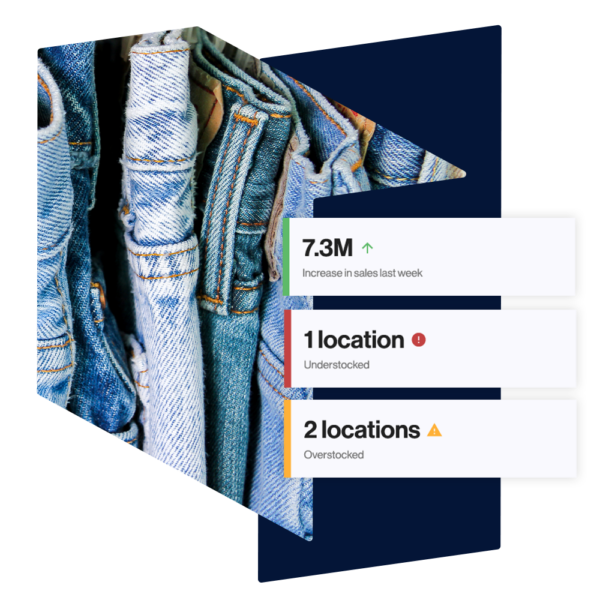

Optimal stock levels at every store

Stock replenishment software to help you sync your stock to demand with product-level replenishment

Inflexible replenishment systems slowing you down?

You’re looking for the optimal stock levels: not too high, not too low, just right. But most replenishment systems aren’t sophisticated enough to automate adjusting to demand at a granular level. That means lots of businesses set replenishment parameters at category level, causing overstocking or stockouts.

Get the gold standard of replenishment

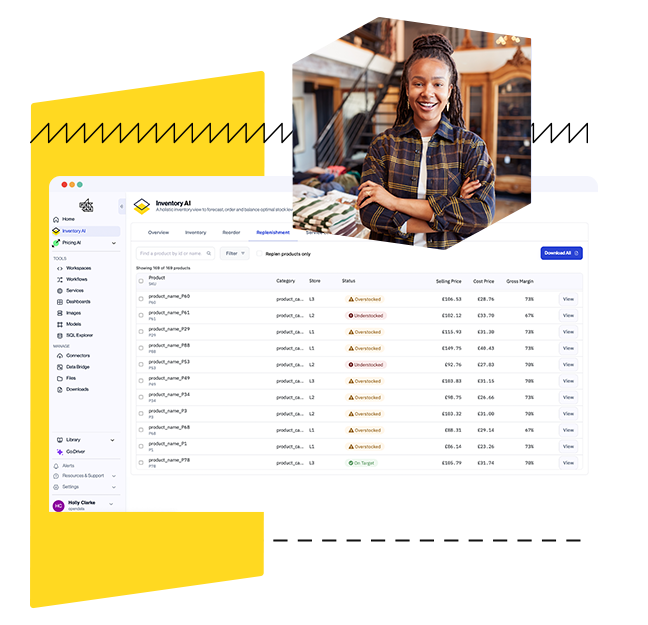

Inventory AI provides inventory replenishment planning software that applies AI models to your data across your whole network. It helps you match quantities of stock with demand, avoiding overstocking and optimizing your return on working capital through better distribution.

Supercharge your inventory replenishment decisions

Ensure the right store and stock cover so you never miss a sale, while balancing inventory so you can free up working capital and streamline distribution operations with our inventory replenishment software.

-

Never miss a sale and avoid stockouts

-

Increase sell-through

-

Free up working capital tied up in aged store stock

-

Increase team productivity & save time

-

Streamline warehouse & distribution operations

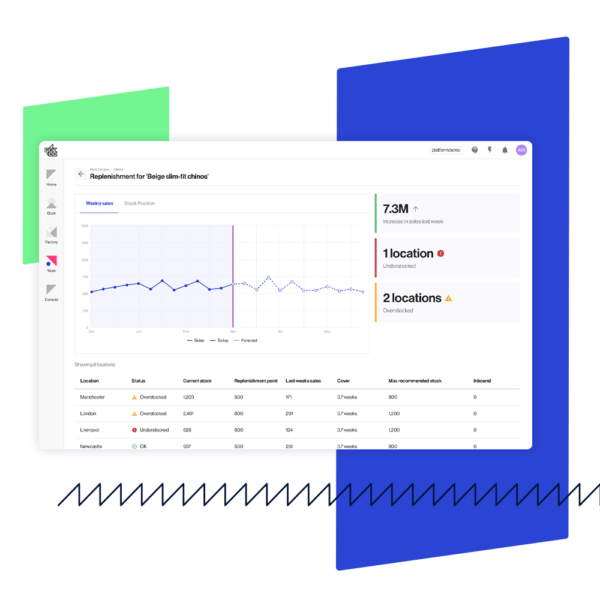

See Inventory AI’s replenishment capabilities in action

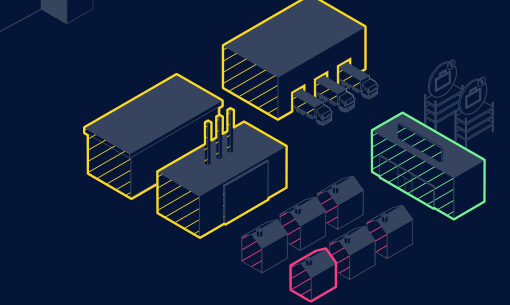

Under the hood

Inventory AI’s Replenishment module is built on Peak’s platform. It uses AI-powered forecasting and stock optimization models to recommend dynamic safety stock levels and replenishment points for every store to ensure you have the right stock cover.

- Combine data

- Add intelligence

- Make decisions

More from Peak

Peak’s approach to demand forecasting

AI for inventory: right stock, right place, right time

FAQs

What is inventory management software?

Inventory management software is a crucial tool for businesses seeking efficient control and optimization of their stock levels. This software streamlines the process of tracking, managing and organizing inventory, offering real-time insights into stock movements, sales trends and order fulfillment.

Effective inventory management involves overseeing stock levels, order processing and maintaining optimal inventory levels to prevent stockouts or overstock situations. Inventory management software automates these tasks, reducing human error and improving overall operational efficiency.

Key features of inventory management software include inventory tracking, order processing, demand forecasting and reporting. Businesses can gain a competitive edge by minimizing carrying costs, preventing stockouts and ensuring timely order fulfillment.

Investing in robust inventory management software not only enhances operational efficiency but also provides valuable data for strategic decision making. By leveraging technology to manage inventory, businesses can streamline their supply chain processes, reduce costs and improve customer satisfaction.

In conclusion, inventory management software is an essential tool for businesses looking to optimize their supply chain, enhance efficiency and make informed decisions based on real-time inventory data. Choosing the right software solution can have a significant impact on a company’s bottom line and overall competitiveness in the market.

What is a stock replenishment system?

A stock replenishment system is a critical component of inventory management that automates the process of restocking products to maintain optimal inventory levels. This system ensures that businesses always have enough stock on hand to meet customer demand while avoiding overstock situations that can tie up capital and resources.

The primary goal of a stock replenishment system is to streamline the supply chain by automating the ordering and restocking process. It takes into account factors such as historical sales data, current inventory levels and lead times to determine when and how much stock needs to be replenished. By utilizing algorithms and forecasting methods, a stock replenishment system helps businesses strike the right balance between supply and demand.

Key features of a stock replenishment system include demand forecasting, order automation and real-time inventory tracking. Businesses can benefit from reduced carrying costs, minimized stockouts and improved order fulfillment efficiency by implementing an effective stock replenishment system.

In today’s fast-paced business environment, where customer expectations are high, having a robust stock replenishment system is crucial. It not only enhances operational efficiency but also contributes to better customer satisfaction by ensuring products are consistently available when needed.

In summary, a stock replenishment system is an integral part of modern inventory management, providing businesses with the tools to optimize stock levels, streamline supply chain processes and ultimately enhance overall operational performance. Choosing the right stock replenishment system can have a significant impact on a company’s ability to meet customer demand effectively and stay competitive in the market.