AI in CPG: supply chain balance

By Stephen Young on January 14, 2020The consumer packaged goods (CPG) industry has been in a state of flux in recent years, and as we move into 2020 we can expect this trend to continue.

The larger players will continue to face competition from digital-first, agile challengers with direct consumer connections – many of which have taken a data-centric approach to their businesses from day one.

Meanwhile, for established CPG companies, a crucial strategy for achieving success this year will be to use machine learning (ML) to create intelligent, dynamic insights – which can be leveraged to drive significant ROI.

Artificial intelligence (AI) has the proven ability to radically improve multiple areas across the modern CPG organization. This could be by enabling businesses to better predict changing customer and consumer demand, or gaining “more bang for their buck” from marketing campaigns and activities. However, in our view, some of the biggest opportunities for AI in the CPG sector can be found in the supply chain.

For the modern fast-moving consumer goods (FMCG) business, being able to handle the flow of products and strategically manage the supply chain is crucial in terms of efficiency, profitability, and also sustainability. With ever-growing product personalization, range, and tens of thousands of stock keeping units (SKUs) to contend with, the siloed, slow approach to harnessing data assets across supply chains, the wider enterprise and partner ecosystem, is no longer feasible.

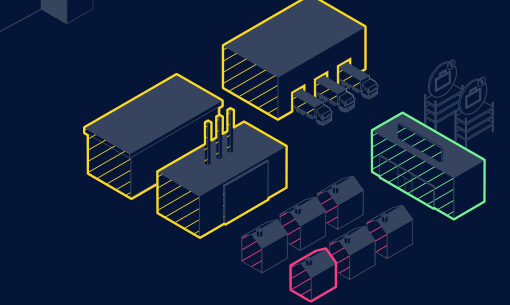

The Supply Chain Triangle concept, created by Prof. Bram DeSmet, is a great way of visualizing the supply chain, and provides a practical framework on which to achieve balance across operations:

As organizations, we deliver different types of service to our customers, which comes at a certain cost and requires a certain amount of inventory, or more generically, cash. The balancing of these three might be the essence of supply chain management.

Prof. Bram DeSmet

CEO at Solventure

If FMCG companies are going to succeed in today’s market, more agile, intelligence-powered solutions are needed to improve demand classification, production planning, stock allocation, and network and customer logistics. Many businesses may already be applying point solutions to tackle individual supply chain problems. However, a centralized AI platform has the unique ability to leverage data and draw learnings from across the entire business in order to achieve that optimal supply chain balance between service, cost, and cash.

One of the most prominent CPG supply chain trends is using AI to unify various data points to improve demand prediction, allowing your business to continually optimize stock and allocation levels of specific products, in the right locations, at the right time.

For an example of this in practice, our case study with equipment hire retailer Speedy is a great place to start — using our Inventory Intelligence applications, we’ve been able to identify significant asset savings through smarter, AI-powered forecasting which has driven a strong increase in return on capital employed (ROCE).

If this of interest, you can book a demo to see our Dynamic Inventory AI application in action here.