An introduction to AI demand forecasting

By Jon Taylor on December 15, 2021 - 15 Minute ReadBusinesses make a lot of important decisions every day. Some are made on cold hard data, while others are based on forecasts and probabilities.

Thanks to AI demand forecasting, making decisions using probabilities has become a lot easier – and a lot more accurate.

Using machine learning algorithms, AI demand forecasting can help businesses predict their supply chain costs and accurately plan for seasonal product fluctuations. Gartner predicts that AI will create $2.9 trillion in value for companies by the end of this year and account for 6.2 billion hours of worker productivity globally.

And, as more companies turn to AI, that number is expected to increase while they benefit from minimizing the cost of cash-in-stock and making better decisions within their supply chain.

This piece is going to break down:

- What is demand forecasting?

- What are the types of demand forecasting?

- How AI will change the demand forecasting in the supply chain

- How is machine learning used in demand forecasting?

- Three real-world examples of AI demand forecasting

Let’s get started!

What is demand forecasting?

Demand forecasting is an analysis of a company’s processes that accurately predicts how much demand there will be for a product or service in the future.

Instead of companies trying to calculate how busy they will be over a certain period, demand forecasting uses historical data and trends to automatically forecast an accurate picture of the future.

Demand forecasting uses artificial intelligence (AI) and machine learning, a subset of AI, to do this. According to McKinsey, companies that use AI-powered forecasting like demand forecasting can cut the errors they make in their supply chain networks by up to 50% as it’s faster, more accurate and more granular than other forecasting methods.

How does it do this, exactly?

If a company is using AI, it can track every part of a supply chain, from how many products a company is selling to when stock will run out (based on SKU numbers.) It also keeps tabs on which products aren’t selling very well (leading to bloated storage costs) and how sales and demand can fluctuate, depending on seasons or the time of year.

Companies that use AI-powered forecasting like demand forecasting can cut the errors they make in their supply chain networks by up to 50%

McKinsey

Benefits of demand forecasting

When it’s time for a company to prepare a demand forecast, they can lean on this data to give them an accurate prediction. More accurate demand forecasts can help a company to…

- Have happier customers – and keep them for longer: Customers will be happier if your product is available anytime, and accurate forecasts help keep your warehouses full enough (but not too full!) in order to meet demand

- Optimize promotions and discounts: Products gathering dust on a shelf cost retailers money. Demand forecasts help to move slow-selling items by predicting what promotions and discounts will peak customer interest

- Get rid of staff shortages: Forecasting staff demand for busy historical periods, or across an entire year, can help businesses optimize workforce planning, such as when to hire seasonal staff

- Get better over time: AI is like a sponge. It uses machine learning to make better forecasts and predictions each time it has access to new data, getting smarter and more accurate over time

- Be more efficient: Demand forecasting helps teams to focus on strategic issues instead of managing unexpected stock fluctuations or dealing with supply chain problems

It’s important to understand that there are several different types of demand forecasting, and that each one has its own requirements and benefits.

AI for inventory: right stock, right place, right time

What are the types of demand forecasting?

In its most basic form, demand forecasting is a way to predict what’s going to happen in uncertain circumstances.

For retailers and businesses dealing with increasingly-complex supply chains, it’s easy to see just how beneficial this could be for stabilizing day-to-day operations. Before choosing a type of demand forecasting to help with a specific prediction, you can automatically take into account any variables you’ll be dealing with, like:

- Constant variations in product demand, sales and seasonal changes

- Marketing and sales activities like product launches or sales

- Factors outside of your control, like competitor movements or supply chain disruptions

Narrowing down exactly what you want to create a demand forecast for will help you pick the right forecasting framework. Six types of demand forecasting are commonly used:

- Short term: Used to make predictions of sales, product demand or any other type of inventory-based forecast needed for a short time frame, typically under 12 months

- Long term: Used to create the same type of forecasts as the short term framework, but over a longer timeframe (typically up to two to four years into the future.) These types of forecasts can also look at things like investment capital, supply chains and logistical issues

- Active: Used to forecast outlooks for sales and marketing campaigns and growth and expansion plans. New companies typically use these types of forecasts to gain investment funding or predict scaling timeframes

- Passive: Used to build demand forecasts if a company has a decent amount of historical data

- Internal: Used for creating internal forecasts to get a more detailed idea about financials, supply chain issues, product demand and overall operations

- External: Used for getting an accurate external projection of overall company health, taking into account competitors, goals and growth

Within each of these frameworks, AI is now playing an increasingly important role in transforming how companies produce demand forecasts. Let’s take a closer look at what that means ?

How AI will change demand forecasting in the supply chain

Ah, just imagine. If only a business could peek into the future and see how much product they would be selling at Christmas time, or what products their customers are most likely to want, in order to make the right decisions every time.

It sounds like a sci-fi movie. But it’s not.

AI demand forecasting has made this a real possibility for companies willing to invest in machine learning and Decision Intelligence solutions. Traditionally, companies use forecasting models like ARIMA or AutoRegressive Integrated Moving Average to predict product demand, but these methods take a lot of manual lifting and leave room for human error.

Tired of being stuck in spreadsheets?

Meet Products, the AI application built to give teams a single source of truth on product performance. Break free from cells with AI!

Instead of relying on humans and traditional forecasting frameworks, companies can use AI demand forecasting to process data much, much faster. It can also uncover problems internally or within a supply chain that a human may miss, and automatically create granular forecasts that help the company make decisions. Decision Intelligence platforms, like Peak, can take this one step further with an end-to-outcome approach to decision making.

This improved analysis can not only save companies a lot of manual working hours, but it’ll be better for revenues and sales. McKinsey found that better AI forecasts can lead to a 65% reduction in lost sales due to out-of-stock inventory. By not storing merchandise that’s selling slowly, warehouse expenses can also be cut by anywhere from 10 to 40%.

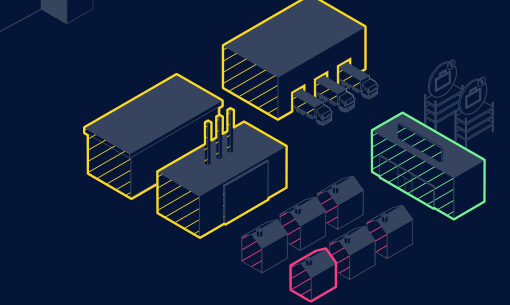

Here’s an example of what adding AI demand forecasting to a supply chain looks like:

With all of this data being analyzed automatically in real-time, it’s easy to see how humans can’t possibly match the detailed level of demand forecasting that AI is capable of.

Now that you know how beneficial demand forecasting can be for a business, let’s take a closer look at how it involves machine learning ?

How is machine learning used in demand forecasting?

Machine learning is a key component of the overall makeup of AI, and it’s extremely useful for getting into the nitty-gritty parts of a company’s datasets.

The problem is that much of this data is going to waste. In fact, nearly 75% of all data collected by businesses isn’t used. Machine learning can take these unused historical datasets and combine them with real-time data to give companies an accurate snapshot of everything, from product demand right through to supply chain issues.

Let’s use a simple grocer as an example.

Christmas is approaching, so the store decides to do what every other store on the planet is doing and run a holiday promotion to boost sales. But how do they decide what products to discount? And how much should they shave off the price tag?

It’s often a guessing game, and often comes down to a human’s own intuition or gut feel. For example, a recent study found that almost 70% of grocers in North America struggle to take in all of the aspects of a sale, like price points and products to promote, when they decide to run a promotion.

Here’s where demand forecasting using machine learning can help. Using the store’s historical datasets to forecast:

- What promotions their customers actually want

- How much their price cuts should be

- What promotional materials (i.e., Facebook ads, letterbox flyers) will be most useful

- Possible shortages in them supply chain or staffing numbers leading up to the sale

This is a lot to consider, and it’s only a fraction of what machine learning could actually do to help the store prepare for its upcoming promotion.

Three real-world examples of AI demand forecasting

We know that terms like machine learning, AI or Decision Intelligence can sound a little daunting to some businesses.

However, you need to remember that AI will do all of the heavy lifting for you. Once you start using AI for demand forecasting, business decision makers don’t really need to know what algorithms it’s using or how machine learning works – it’s the forecasts themselves that’ll help you and your business.

Here are three examples to help demystify the AI demand forecasting process ?

Scenario one: when a company is experiencing rapid growth

Every company starts somewhere, but one of the biggest decisions a new, growing company needs to make is when to ramp up production.

While monthly revenue may look promising, scaling a company requires additional investment and hiring more staff – a big decision to make if the data doesn’t back it up. AI demand forecasting can use the company’s historical datasets to create a more accurate picture of its current growth and predict what the next year will look like.

For example, AI can dig into the company’s sales and see that it’s averaging about 15,000 product sales a month, but that it’s increasing 10% each month. It can quickly calculate what this level of growth will mean over the next 12 months for the company and forecast growth numbers, like how much stock they should have to keep up with demand and when they may need to hire additional staff in operational or supply chain jobs.

AI will also take this demand forecast and assist if the company decides to ramp up its operations by offering other suggestions, like more space to store stock or running promotions on popular products.

Scenario two: when there are too many supply chain factors to consider

We want you to think about pizza for a minute ?

It may seem like a simple dish. But put yourself in the shoes of a company that sells fresh pizzas to national supermarket chains, and suddenly there’s a lot to think about when making and selling their pizzas.

Price fluctuations of flour, cheese, tomatoes and even packaging do happen. And if the company doesn’t keep on top of these pricing fluctuations and react to them, it can eat into its profit margins.

AI demand forecasting can take historical data and scan it to see any patterns within price fluctuations of previous years. Does flour increase in price when farmers are not harvesting? Where does the company source the cardboard pizza boxes from, and are they always the same price?

AI and machine learning algorithms can learn from pricing fluctuations in the past and help the pizza maker prepare for any changes. The goal here is for the AI demand forecast to account for any minimal fluctuations so the company can set stable prices for its customers without increasing them each time there is a fluctuation.

The company also needs to consider the number of fresh ingredients it must keep in stock to meet demand. AI demand forecasting can match the pizza company’s product ranges to variations in customer demand across the stores it’s selling to. It can then forecast allocation, replenishment, and assortment planning so the company can meet the supermarket’s order demands without risking wastage by stockpiling too many fresh ingredients.

Scenario three: when there is no historical data to use

AI demand forecasting isn’t just for companies with huge historical data sets – it can help companies navigate with situations that they’ve never had to deal with before.

Let’s take a very recent example: the COVID-19 pandemic. The majority of companies had most likely never dealt with a situation where their customers were stuck at home or supply chains ground to a halt.

This is exactly what UK concrete and natural stone paving manufacturer, Marshalls, faced when the pandemic hit. The company went from holding excess stock to facing a world where the stock was in short supply overnight. It created a very volatile environment, and the company was forecasting inventory levels and managing order fulfillment manually.

It was a lot of manual lifting, so the company decided to integrate AI into its system to help with inventory optimization while still driving growth in a worldwide lockdown. Using Peak’s demand planning and forecasting solutions, Marshalls passed the manual decision making over to AI and started getting answers to critical questions like:

- How much inventory should the company produce?

- What are the minimum levels of stocks the company should hold in each location to meet demand?

- How should order fulfillment be prioritized?

Soon, the platform was making 4000 AI-powered demand forecasting decisions every single day for Marshalls, helping the company navigate the almost £300,000 of orders it takes daily and giving data-backed advice on which ones should be prioritized.

Wrapping up

AI demand forecasting is changing how companies control their supply chains and make decisions.

Instead of relying on manual processes, AI demand forecasting collects and combines data sets and analyzes them for patterns and problems. The result is that companies can make decisions about anything from stock buying to pricing markdowns not on a whim but using demand forecasts backed with cold, hard data. Here at Peak, we help companies like yours integrate AI demand forecasting into your digital systems to help make smarter decisions. That’s why we call it Decision Intelligence! With our DI platform, we’ve helped businesses like KFC, AO, Footasylum and Speedy implement this technology to get the most out of their tech stacks – you can read more about their success here.

Interested in exploring the potential of AI-powered demand forecasting?

We'd love to walk you through how we could help your business. Book a demo to see our Dynamic Inventory application in action.

More from Peak on demand forecasting